Mold Manufacturer

100% quality and service satisfied guarantee

Our Services

Building Construction

Part design

Prototyping

Prototyping manufacturing

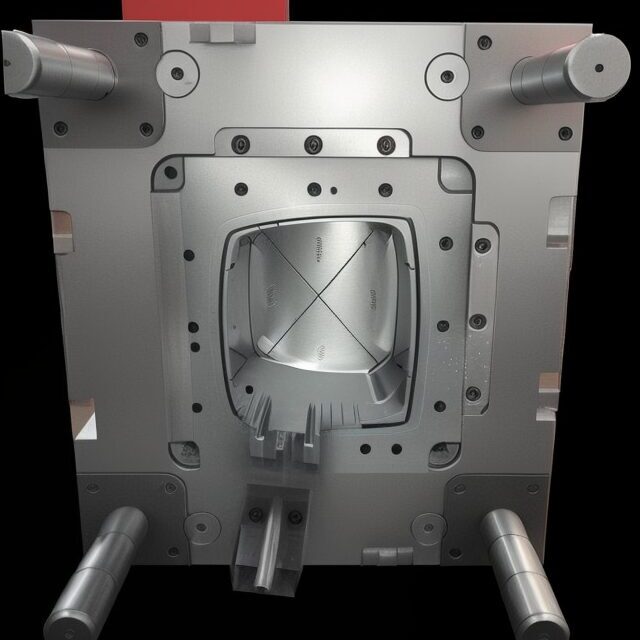

Mold Manufacturing

Mold design, mold manufacturing

Machining

CNC machining, turning, cutting, etc.

Assembly Service

Products assembly and certificate

Need A China Mold Manufacturer?

Why choose Sincere Tech as your Mold Manufacturer

- Signing an NDA (Non-disclosure agreement) document to protect your project.

- DFM (design for manufacturability) analysis report to solve any possible issue (sink marks, demoulding issue, undercut analysis, sharp steel, etc) before mould manufacturing.

- Mold Components for all of export molds are made according to DME, HASCO standard, or according to customer’s requirement

- All of export molds are shipped with steel certificate, heat treatment certification, mold trial parameter, and full-dimension measurement report according to customer’s 2D drawing

- Fluent technical English communication & excellent project management.

- 15+ years of experience in Making, Die Casting, Plastic Molding Manufacturing, Painting, Silk Screen, and Part assembly.

- One stop service from design, prototyping, testing, PCB soldering, certificate, assembly & delivery.

- A few hundred of quantity or millions of quantity parts are available for your market needs

Latest Projects

Die Casting Mold

Project Title

CNC machining

We’ve Been Building For Over 10 Years

We provide a comprehensive product design service based on your ideas, samples, or sketches. Our products range from home appliances, digital devices, industrial parts, toys, beauty tools, to health care products.

We have our own mold manufacturer and molding shop where we can create plastic molds, metal tooling, die casting, stamping tools, machining, and post-manufacturing processes such as painting, silk screen, pad printing, and ultrasonic welding.

Our all-in-one service includes prototyping, testing, re-prototyping and testing until final approval. Once the design is complete, we move on to the prototyping stage. We handle everything from production, certification, PCB soldering, electronic assembly, inspection, packing, and delivery.

OEM/ODM factory

Design, mold manufacturing, assembly

Let’s Build Your project in life

We provide a comprehensive product design service based on your ideas, samples, or sketches. Our products range from home appliances, digital devices, industrial parts, toys, beauty tools, to health care products.

We have our own mold manufacturer and molding shop where we can create plastic molds, metal tooling, die casting, stamping tools, machining, and post-manufacturing processes such as painting, silk screen, pad printing, and ultrasonic welding.

Our all-in-one service includes prototyping, testing, re-prototyping and testing until final approval. Once the design is complete, we move on to the prototyping stage. We handle everything from production, certification, PCB soldering, electronic assembly, inspection, packing, and delivery.

How many engineer do work in Sincere tech?

There are 20 engineers work as mold designer & CNC programmer, and 10 engineers work as project engineer. 5 engineers work as CNC machined programmer, 12 engineers work as die casting mold designer & CNC programmer

Can you provide the steel certificate and heat-treatment certificate?

Yes, we can. The steel supplier and heat-treatment factory can provide the certificates.

Which foreign customer has been cooperated with you?

Our foreign customer mostly in Europe, America, Australia and Asia, South African, etc.

What is your payment term?

For new mold, 40% deposit, 30% on first article, 30% before production or shipment. For mold EC, 100% after EC samples delivered. For prototype mold, 50% with order and rest 50% after samples delivered. For CNC machine parts, 50% with order, and rest 50% after parts delivered. For production, 50% with order and 50% after parts delivered.

How many square meters working shop of the Sicere tech mold manufactory?

Our manufactory working is 6000 square meter. Which is including one mold factory, a molding shop, a product assembly shop and die casting factory

What size molds and parts you can products?

Molds up to a product length of 2 meter and up to 15 tons weight. plastic molding parts we can produce up to 7kg, die casting parts we can produce up to 23kg.

What kind of steel do you use for mold inserts?

We can use all types of steel appointed by customer. Usually we use 1.2344, 1.2343, H13, S136, 8407 and LKM steel ,etc.

What type of CAD Files is acceptable for you?

IGS, STEP, X_T, PRT, DWG, STL, DXF, PDF etc. CAD formats are acceptable for us.

Client Testimonials

Contact Us

Dongguan Sincere Tech Co., Ltd

Add: Rm101, Number 2, Street 11, Wen Ming South Road, Qiaotou, QiaotouZhen, Donggguan City, Guangdong Province, China. 523000.

Weichat/whatsup No.: + 86 135 3080 1277